OEM Mechanical Seal

UPSEALONE manufacture only 100% high quality warranted MECHANICAL SEALS

- Advanced manufacturing technology and quality management controlled ISO 9000.

- High quality materials, optimum quality following ISO, ANSI, DIN and API Standards.

- Excellent quality delivered with FULL OEM UPSEALONE warranty.

- Fast delivery time at competitive pricing

We achieve that through:

1 – ANALYSIS

2 – MANUFACTURING

1 – ANALYSIS

FULL ANALYSIS OF YOUR SEALING EQUIPEMENT and REQUIREMENT

Full expertise (wear surface, material structure, controlled dimensions) by our trained technical staff.

Rebuild option could also be done depending on cost analysis, delivery time and customer choice after expertise.

STUDY CASE:

Day 1:

We picked up at customer mill the old John Crane mechanical seal for expertise.

Day 2:

After a full control, the material structure and dimensions were too worn to be repaired.

Our Technical team preferred to offer a safety solution manufacturing a complete new mechanical seal at 50% OEM cost!

Day 3:

Customer approved this approach, repairing is sometimes higher cost than a new part with full dimension warranties!

FAST and SAFETY!

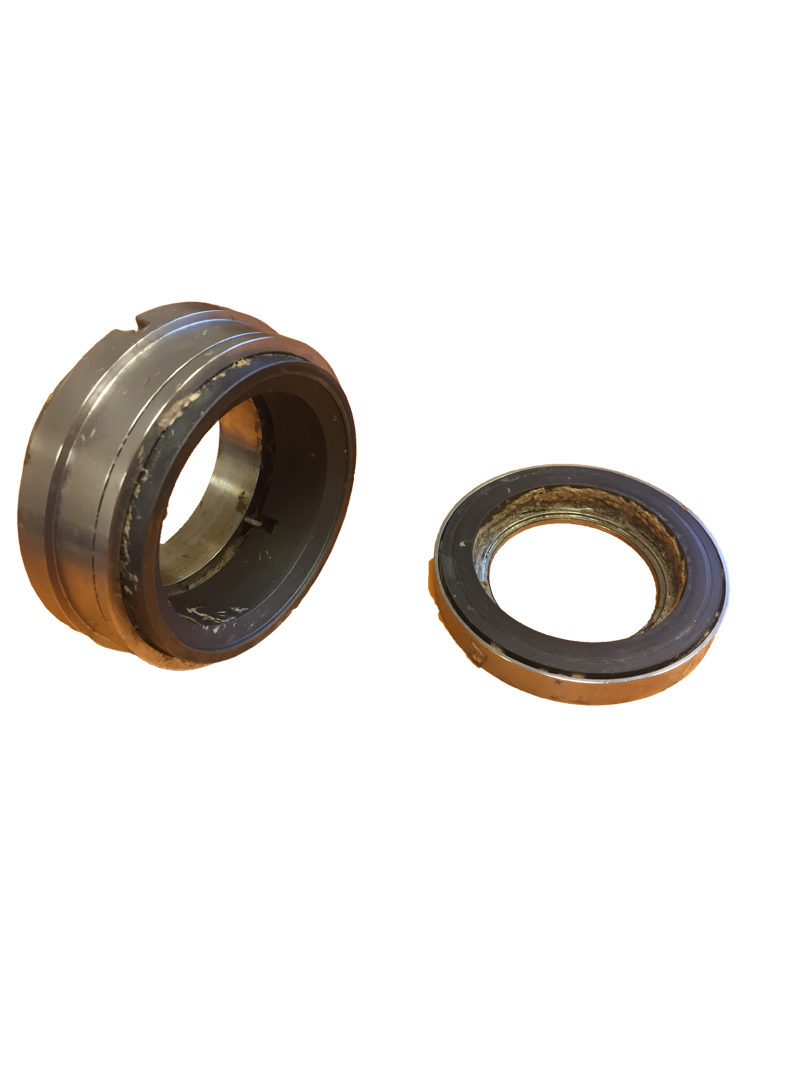

John Crane Mechanical Seal received for Expertise

Mounted on Andritz S series pump.

USED – Mechanical Seal John Crane (Andritz pump) 587

Expertise of used customer mechanical seal

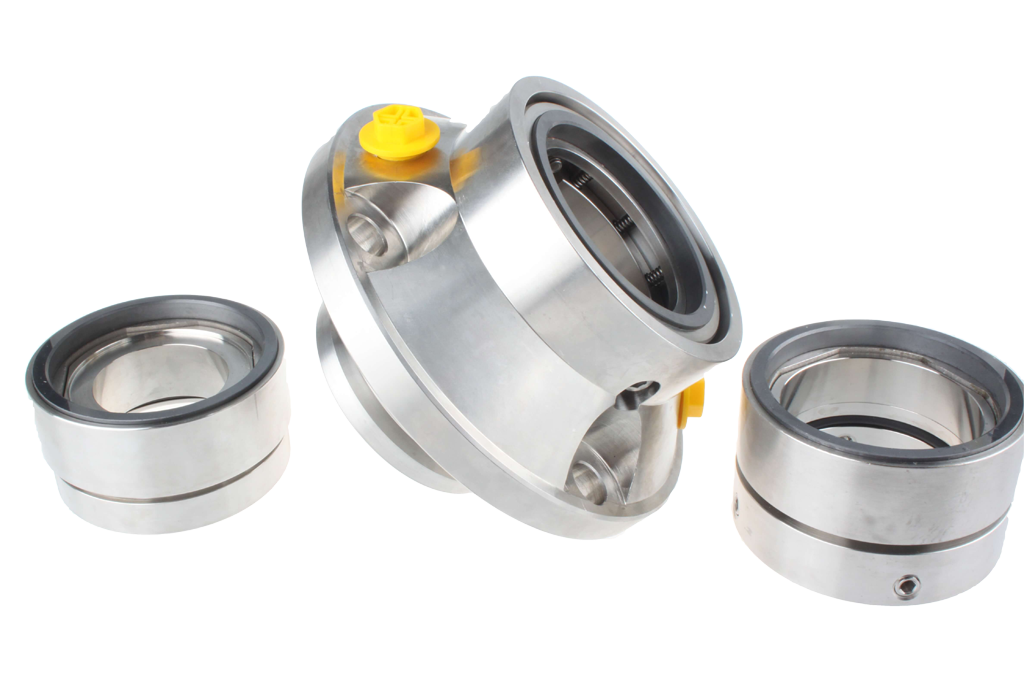

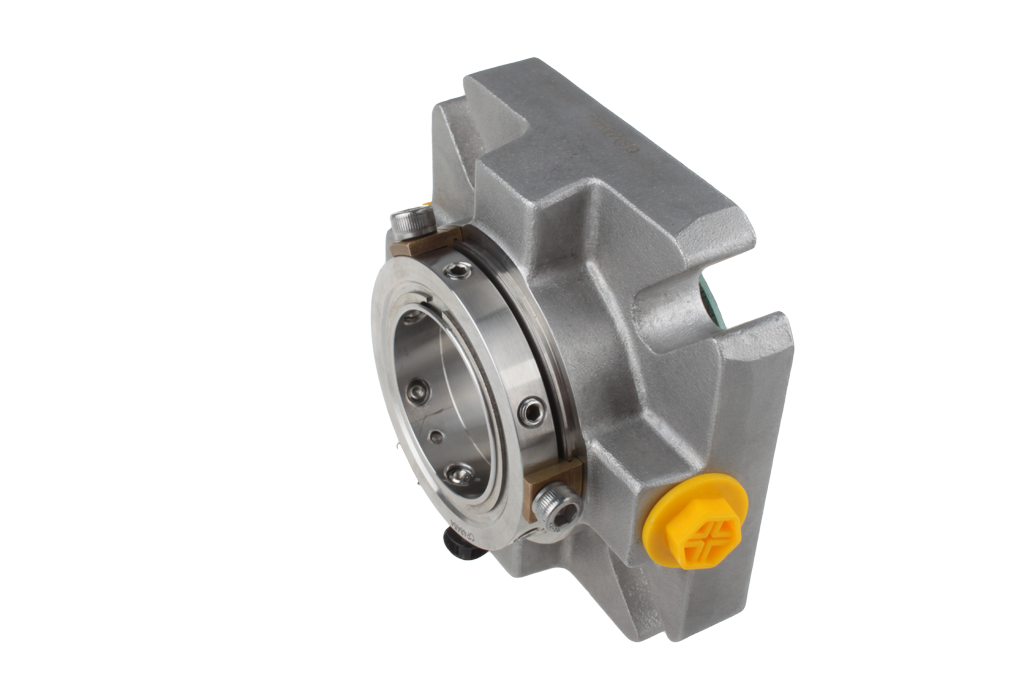

NEW – UPSEALONE Mechanical Seal designed DS587 series

Manufacturing upon technical request

Immediate delivery. Strong double packaging, drawing, control data sheet and UPSEALONE OEM warranty with identification sticker.

Delivered day+1 with DHL / UPS / FEDEX / TNT etc.

2 – MANUFACTURING

UPSEALONE HIGH QUALITY MANUFACTURING of SEALING EQUIPMENT

Example of use: Pulp and paper, Marine, Chemicals, Power industry, Petrochemical, Pharmaceuticals, Waste water, Slurry, Food and Beverages, (Pumping applications: For Sulzer pumps, mixers and agitators, Andritz pumps, Moret pumps, ABS-Scanpump pumps, Flowserve Durco pumps, ITT Goulds Flygt pumps, Lowara, Grundfos, Allweiler, Netzsch, Seepex, Bornemann, Wangen, Mono, Moineau, Etc).

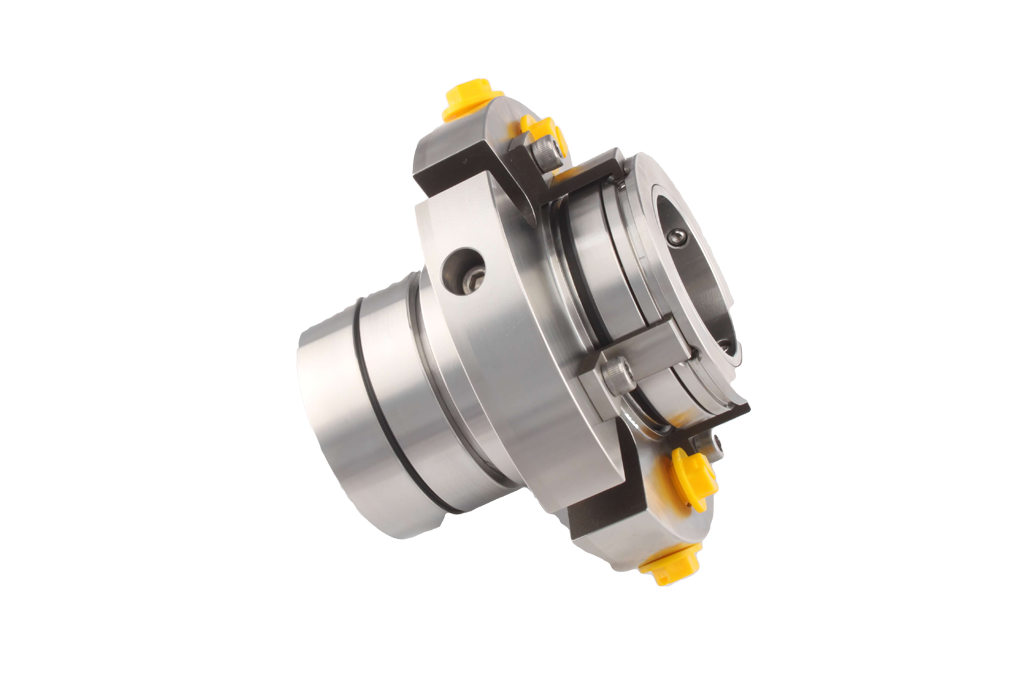

Types: Cartridge seals, metal bellow seals, pump seals, mixer seals, agitator seals and many more upon request!

Replacement for Burgmann, John Crane, AESSEALS, etc.

Multi-Springs Standard Seal – UPSEALONE DSE2 series

Alternative for Safematic SE2 type / SULZER pumps

Mechanical Seal – UPSEALONE DSMIX series

For SULZER Salomix Mixers series

Mechanical Seal – UPSEALONE DS365 series

For chemicals, pulp and paper applications

Mechanical Seal – UPSEALONE DSGRUND series

For GRUNDFOS pumps

Single Cartridge Seal – UPSEALONE DSCS series

For water, corrosive chemical liquid, low concentration slurry, oil and some solids mixed.

Mechanical Seal – UPSEALONE DS221 series

For pulp, chemical liquid applications

Single Cartridge Mechanical Seal – UPSEALONE DSCP series

Especially designed for progressive cavity pumps (screw pumps) like MONO, MOINEAU, NETZSCH, ALLWEILER, SEEPEX, BORNEMANN, WANGEN, PCM etc.

Mechanical Seal – UPSEALONE DSLOW series

For ITT LOWARA pumps

Double Mechanical Seal – UPSEALONE DSB2 series

For special beverage, paper and chemicals applications.

Single or Double Cartridge Seal – UPSEALONE DSFLOW series

Designed for GOULDS 3196 series STX MTX LTX SLT-X, ANSI standard, for FlOWSERVE Group I , II, III, for DURCO pump, chemical processing pumps.

Proven 50% efficiency better than Flowserve original seal performances!

Double Mechanical Seal – UPSEALONE DSD13 series

For chemicals, pulp and paper applications

Metal Shaft Sleeve – UPSEALONE DSIMO series

For IMO pump, marine, oil fuel applications

Teflon Bellow seal – UPSEALONE DSTB series

Example: Sulzer* type TB1 / TB2 series

UPSEALONE – DSF series

For ITT* FLYGT* range

Pressure screen range – UPSEALONE PSCREEN series

OPTION: Analysis, installation and maintenance on site by experimented UPSEALONE teams

Designed for all pressure screen machines like VOITH* / AHLSTROM* / AFT* / METSO* / VALMET* / BELOIT* / ANDRITZ* / BLACK CLAWSON* / LAMORT* / KADANT* etc.

JUST ASK US FOR MORE INFORMATIONS

Our UPSEALONE Specialist team will answer directly to your questions!

MECHANICAL SEALS

Diamco Group and Upsealone are not affiliated nor a distributor for any other company mentioned. The pumps and parts manufactured by us are not associated with, endorsed by, or sponsored or manufactured by the owners of the related trade marks given into this website or other documents. Any use of OEM names, trademarks or other information is for reference only.