Netzsch * Replacement Pump

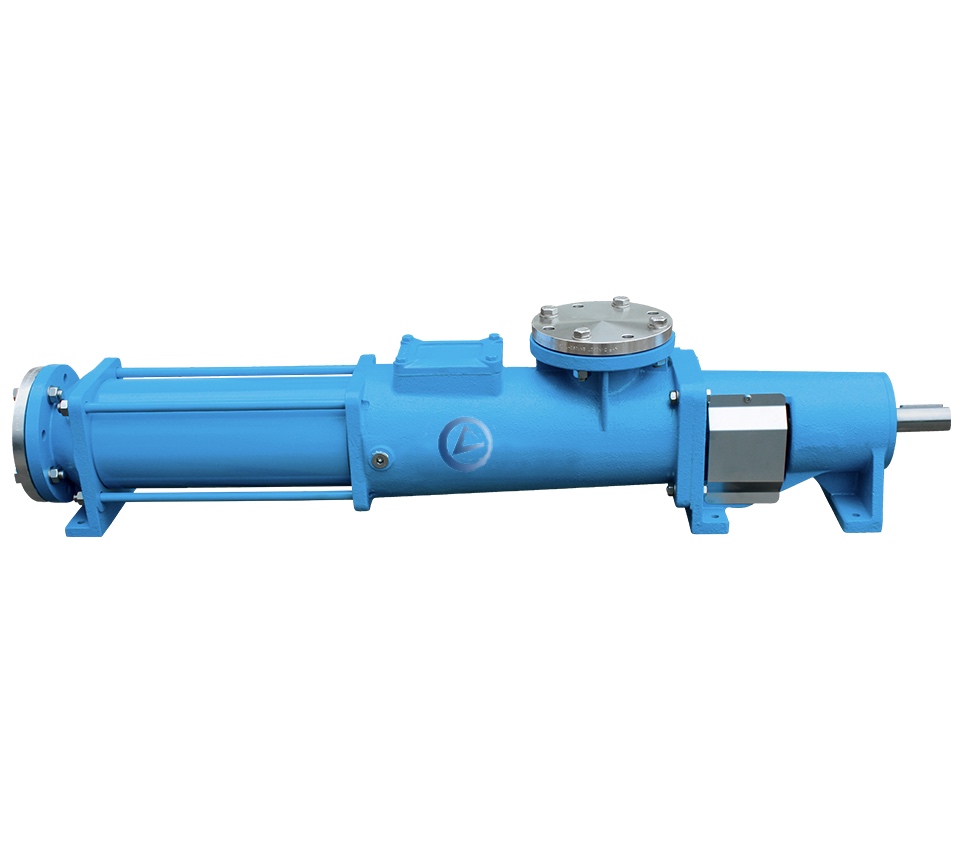

Special DIAMCO NE range – 100% Netzsch NE * replacement pump

Diamco manufacture complete pumps with motor and baseframe, rotating assemblies and individual parts for all Netzsch NE Pumps NEMO®. All our replacement parts will fit your Netzsch NE serie pumps in all configuration. Originally, Netzsch pumps NEMO® NE series came with two main different types of joint, pin and gear joint style. Diamco shorten deliveries and reduce your total cost of ownership in both types of configuration.

Defined by the model number, as original Netzsch NE pumps, the Diamco NE pump series came with different style of of rotor and stator geometry. Netzsch NE70, NE69, NE90 and NE89 use the same drive end of the Netzsch NE60 and NE80 respectively in a single stage configuration. However, the “pitch” which is the geometry of the rotor and stator is more elongated increasing the velocity and evidently the flow of the media being pumped. These two models of Diamco NE pumps are specially useful where the application requires a higher GPM mantaining the energy consumption of a smaller drive end.

As OEM pump manufacturer, Diamco provide a FULL 100% warranty and reliability

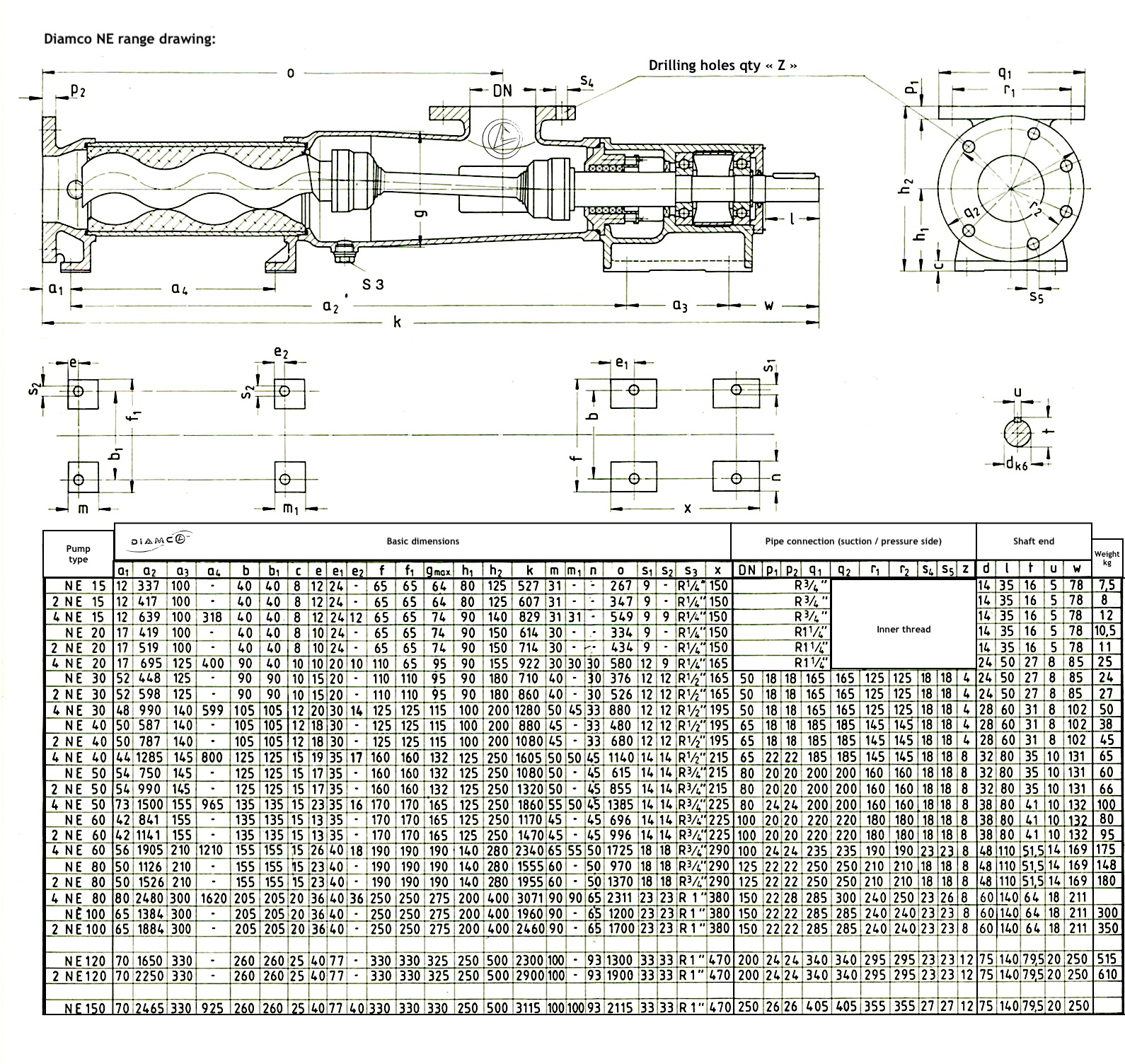

100% INTERCHANGEABLE MODELS:

- Equivalent models manufactured by Diamco are:

- Diamco NE15 pump size as: Netzsch NE15, Netzsch 2NE15, Netzsch 4NE15.

- Diamco NE20 pump size as: Netzsch NE20, Netzsch 2NE20, Netzsch 4NE20.

- Diamco NE30 pump size as: Netzsch NE30, Netzsch 2NE30.

- Diamco NE40 pump size as: Netzsch NE40, Netzsch 2NE40, Netzsch 4NE40.

- Diamco NE50 pump size as: Netzsch NE50, Netzsch 2NE50, Netzsch 4NE50.

- Diamco NE60 pump size as: Netzsch NE60, Netzsch 2NE60, Netzsch 4NE60.

- Diamco NE80 pump size as: Netzsch NE80, Netzsch 2NE80, Netzsch 4NE80.

- Diamco NE100 pump size as: Netzsch NE100, Netzsch 2NE100.

- Diamco NE120 pump size as: Netzsch NE120, Netzsch 2NE120.

- Diamco NE150 pump size as: Netzsch NE150.

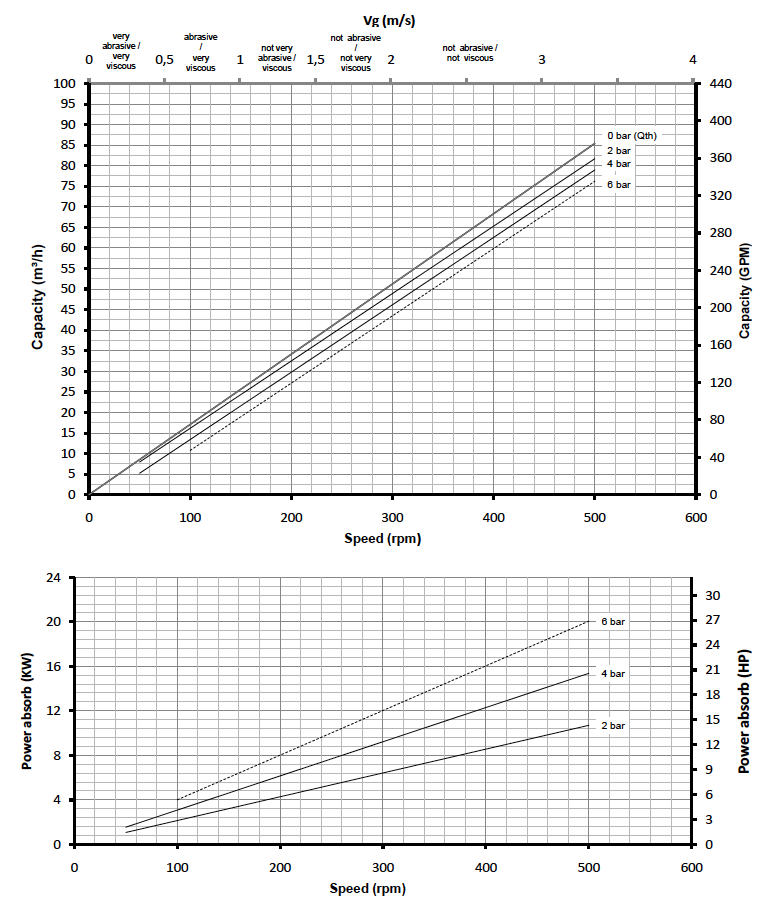

TECHNICAL DATAS:

- Liquids: Clean and slightly contaminated, viscous, fibrous or non-fibrous slurries, large and hard solids containing liquids.

- Temperature up to 260°C / 500°F

- Capacity and pressure: up to 500m3/h for pressure up to 48 bars.

- Use as: Standard pump, dosing pump, food (FDA) approved pump, etc.

- Liquid position below or above the pump

- Corrosion pH from 0 up to 14

- Wear resistance innovative and PATENTED solutions to abrasion, corrosion, cavitation, erosion and chemical attacks.

ADVANTAGES:

- Large range of reliable and efficient manufacturing options enables fast and easy dismantling-reassembly during shutdown.

- Heavy-duty shaft and bearing unit (oil or grease lubrificated) extending shaft lifecycle and reducing unexpected shutdowns and maintenance costs.

- Modular design adapted for specific applications (liquids, solids, capacities, heads, temperatures, frequencies 50 or 60Hz and pressures) with a large range of materials available as follow:

- ROTORS: We manufacture our standard material of construction depending on customer requirements. Available qualities are: Stainless Steel 304, 316, 304L, 316L, 329, 329Ti, tool steel, hardened steel, 1.4571 stainless steel, HV and HVC types. Diamco offers a large of different coating options to resist to wear applications.

- STATORS: We manufacture customized rubber and special materials for Netzsch NEMO® pumps when necessarily suitable for the application. From our standardized rubber, we always verify the most affordable solution to the rigorous applications. Available qualities are: Hypalon, Teflon, Buna, NBR, NBR Light, EPDM, EPDM Light, FPM, CSM, FKM, Viton, and many more.

- A large selection of our own manufactured sealing devices adapted to particular liquids and applications (gland packing, mechanical seal (single-double), dynamical shaft seal, lippseal, cartridge seals…)

INTERCHANGEABILITY:

- All our Diamco NE type pump range is standardized and 100% of dimensions manufactured as original series for complete interchangeability.

- Common sealing water equipment.

- Common baseplates/baseframes (different alloys upon request).

- Lower spare part inventory with high interchangeability of wet ends.

JUST ASK US FOR MORE INFORMATIONS!

DIAMCO NE REPLACEMENT PUMP * for NETZSCH NE pump

Diamco Group is not affiliated nor a distributor for any pumps company mentioned. The pumps and parts manufactured by us are not associated with, endorsed by, or sponsored or manufactured by the owners of the related trade marks given into this website or other documents. Any use of OEM names, trademarks or other information is for reference only.